Stop Guessing. Start Spraying Right.

Choosing between an electrical airless spray machine and a pneumatic (air-operated) airless machine isn’t just a technical decision—it’s a critical business decision that affects your project timeline, safety compliance, finish quality, and bottom line.

At Shree Bissa Engineering (SBECOAT), with over a decade of experience as India’s leading industrial painting equipment manufacturer, we’ve helped thousands of contractors, fabricators, and plant managers make this exact choice. This comprehensive guide distills our field expertise into actionable insights you can use today.

Executive Summary: Which Machine Wins for Your Application?

| Your Application | Recommended Type | Key Reason |

|---|---|---|

| Structural Steel Painting | ✅ Electrical | Cost-effective, portable, perfect for site work |

| Factory Maintenance Painting | ✅ Electrical | Easy operation, minimal setup |

| Oil & Gas / Refinery Projects | ✅ Pneumatic | Hazardous area safety, no spark risk |

| Shipbuilding & Marine | ✅ Pneumatic | Continuous operation, handles thick coatings |

| Construction Contracting | ✅ Electrical | Mobility, lower operating cost |

| Chemical Plant Maintenance | ✅ Pneumatic | Explosion-proof operation |

| Heavy Epoxy/Intumescent Coating | ✅ Pneumatic | Superior high-viscosity handling |

Chapter 1: Understanding the Core Technology

How Airless Spraying Works (Both Types)

Both electrical and pneumatic airless machines operate on the same fundamental principle: hydraulic pressure.

- A pump creates extremely high pressure (typically 2,000-3,000 PSI)

- Paint is forced through a small orifice in the spray gun tip

- The paint atomizes into fine particles without compressed air

- Result: Faster application, better penetration, less overspray

The key difference lies in what powers that pump.

Chapter 2: Electrical Airless Spray Machines – The Contractor’s Choice

Technical Specifications & Capabilities

- Power Source: 220V AC, Single phase (generally)

- Flow Rate: 1.5 – 3.5 GPM (Gallons Per Minute)

- Pressure Range: 500 – 3,300 PSI

- Max Viscosity: Up to 5,000 cPs

- Typical Applications: Primers, enamels, PU coatings, acrylics, textures

Who Should Choose Electrical? (Ideal User Profile)

✔ Construction Painting Contractors

✔ Industrial Maintenance Teams

✔ Fabrication Shop Owners

✔ Infrastructure Project Managers

✔ Paint Applicators needing mobility

Real-World Case Study: Bridge Painting Project

Challenge: Paint 25,000 sq.m of structural steel with epoxy primer and polyurethane topcoat within 45 days.

Solution: SBECOAT recommended 2× Electrical Airless Spray Pumps (3.0 GPM, 3000 PSI) with:

- 100m reinforced hose lines

- Reversible tips for clog prevention

- Mobile generator backup

Result: Project completed in 38 days with 40% less paint consumption compared to conventional spraying.

Chapter 3: Pneumatic Airless Machines – The Industrial Powerhouse

Technical Specifications & Capabilities

- Air Requirement: 20 – 60 CFM at 80-100 PSI

- Air-to-Paint Ratio: Typically 1:1 to 2:1

- Pressure Range: Up to 5,000 PSI (specialized models)

- Max Viscosity: Up to 10,000+ cPs

- Hazardous Area Ratings: ATEX, IECEx Zone 1/2 certified options

Who Should Choose Pneumatic? (Non-Negotiable Applications)

⚠️ Mandatory Choice When:

- Working in flammable/explosive atmospheres (Zone 1, Zone 2)

- Spraying intumescent fireproofing coatings

- Applying 100% solids epoxy in tank linings

- 24/7 production line operations

- Offshore platform maintenance

Safety First: Why Pneumatic Wins in Hazardous Zones

Electrical equipment in explosive atmospheres requires:

- Intrinsically safe design

- Expensive certification (ATEX, IECEx)

- Regular compliance checks

Pneumatic machines eliminate this entirely. No electricity means no spark risk, making them inherently safe for:

- Oil refineries

- Chemical storage areas

- Fuel tank interiors

- Gas pipelines

Chapter 4: Head-to-Head Comparison Table

| Parameter | Electrical Airless | Pneumatic Airless | Winner For |

|---|---|---|---|

| Initial Investment | ₹65K – ₹1.5L | ₹95k – ₹1.4L + Compressor | Electrical |

| Operating Cost/Hour | ₹50-100 (electricity) | ₹150-300 (compressed air) | Electrical |

| Portability | Excellent (wheel cart) | Good (needs air line) | Electrical |

| Hazardous Area Use | Not recommended | Perfect | Pneumatic |

| Continuous Operation | 4-6 hours recommended | 24/7 capable | Pneumatic |

| Viscosity Handling | Good (up to 5K cPs) | Excellent (10K+ cPs) | Pneumatic |

| Maintenance Complexity | Medium (electrical parts) | Simple (air motor) | Pneumatic |

| Setup Time | 15-20 minutes | 30-45 minutes (air setup) | Electrical |

| Typical Lifespan | 3-5 years | 7-10+ years | Pneumatic |

pneumatic has higher initial cost, its value in hazardous areas is irreplaceable. For non-hazardous work, electrical provides 20-50% lower total cost.

Chapter 5: Common Mistakes to Avoid

Mistake #1: Using Electrical in Zone 1 Areas

Risk: Catastrophic explosion, legal liability, criminal charges

Solution: Always conduct area classification assessment before equipment selection

Mistake #2: Undersizing Air Supply for Pneumatic

Consequence: Poor atomization, uneven coating, pump damage

SBECOAT Rule: Air supply CFM should be 1.5× machine requirement

Mistake #3: Ignoring Viscosity Requirements

Example: Trying to spray 8,000 cPs intumescent with standard electrical pump

Result: Pump failure, project delays

Fix: Match pump type to coating data sheet specifications

Chapter 6: SBECOAT’s Expert Selection Framework

Our 5-Point Decision Matrix

Answer these questions to get your perfect match:

- Location Safety: Is it a hazardous/classified area?

→ Yes = Pneumatic | No = Proceed to Q2 - Coating Type: Viscosity above 5,000 cPs or 100% solids?

→ Yes = Pneumatic | No = Proceed to Q3 - Operation Time: Continuous 8+ hour daily operation?

→ Yes = Pneumatic | No = Proceed to Q4 - Budget Priority: Capital cost sensitivity?

→ High = Electrical | Low = Proceed to Q5 - Future Flexibility: Multiple site vs fixed location?

→ Multiple sites = Electrical | Fixed plant = Pneumatic

Chapter 7: Industry-Specific Recommendations

For Fabrication Shops & OEMs

Recommended: Electrical Airless

Why: Multiple coating types, non-hazardous environment, cost sensitivity

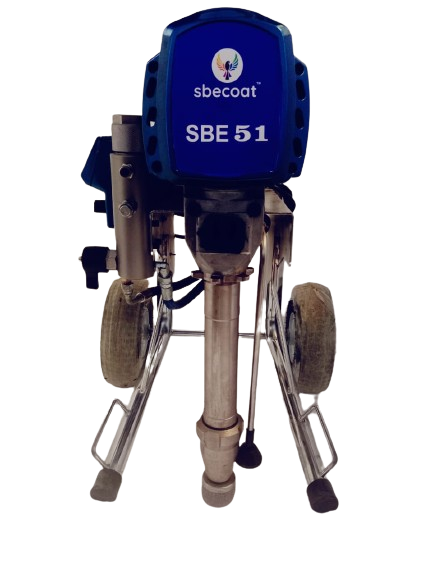

SBECOAT Package: SBE 25 E-AIRLESS

For Oil & Gas Turnaround Contractors

Recommended: Pneumatic Airless

Why: Hazardous zones, thick epoxies, continuous operation

SBECOAT Package: PAS-4000 + compressor + explosion-proof lighting

For Infrastructure Companies

Recommended: Electrical Airless

Why: Site mobility, various substrates, contractor preference

Chapter 8: Frequently Asked Questions

Q1: Can I convert an electrical machine to pneumatic?

A: No. The internal mechanisms are fundamentally different. It’s more cost-effective to purchase the correct type initially.

Q2: What about battery-powered airless sprayers?

A: These are for light-duty/decorative applications only. For industrial coatings, you need the consistent power of electric or pneumatic.

Q3: How do I maintain my airless spray pump?

A:

- Daily: Filter cleaning, tip inspection

- Weekly: Packing adjustment, fluid section check

- Monthly: Motor/air motor inspection

- SBECOAT offers AMC packages starting at ₹15,000/year

Q4: Does SBECOAT provide onsite training?

A: Yes. Every machine purchase includes:

- 2-hour operator training

- Maintenance workshop

- Safety protocol demonstration

- Troubleshooting guide

Chapter 9: Next Steps – Get Your Personalized Solution

Why Choose SBECOAT as Your Partner?

✓ 15+ Years industrial painting expertise

✓ Complete solutions (machine + compressor + accessories)

✓ After-sales network across ALL India

✓ Project consultation at no extra cost

Get a Custom Recommendation

Option 1: Complete our Project Assessment Form

Option 2: Schedule a 15-Minute Technical Call with our experts

Option 3: Visit our Demo Facility in Gandhidham, Gujarat Location (Live testing available)

Final Verdict

Choose Electrical Airless When:

- Working in non-hazardous areas

- Budget and mobility are priorities

- Coating viscosity is below 5,000 cPs

- Operation is intermittent (not 24/7)

Choose Pneumatic Airless When:

- Safety compliance is non-negotiable (hazardous zones)

- Spraying high-viscosity or specialty coatings

- Continuous production operation

- Long-term durability outweighs initial cost

📞 Ready to Transform Your Painting Operations?

Contact SBECOAT Experts Today:

- Call: +91-84870-85228

- Email: sbecoat.india@gmail.com

- WhatsApp: +91-84870-85228

“Don’t just buy equipment—invest in the right productivity solution.”

– Shree Bissa Engineering (SBECOAT) Team